Fire Fighting Pumping Systems / Pumps

We are Manufacturer, Supplier, Exporter (and also Services Provider) of Fire Fighting Pumping Systems ( Fire Fighting Pumps ), Fire Fighting Main Electrical Pumps ( Electric Motor Driven Fire Pumps), Fire Fighting Diesel Engine Pumps ( Fire Fighting Standby Pumps ), Fire Fighting Jockey Pumps, Multistage Fire Fighting Pumps, Multi Outlet Fire Fighting Pumps, Fire Booster Pumps, Mono Block Pumps and our setup is situated in Pune, Mumbai, Ahmednagar, Nagpur ( Maharashtra, India ).

Fire Fighting Pumping Systems

A Fire Fighting Pumping Systems ( Fire Fighting Pumps ) is a part of a Fire Sprinkler Systems water supply and powered by electric, diesel. The Pump intake is either connected to the public underground water supply piping, or a static water source (e.g., tank, reservoir, lake).

The Fire Fighting Pumping Systems ( Fire Fighting Pumps ) provides water flow at a higher pressure to the sprinkler system rises and hose standpipes. Fire Fighting Pumping Systems / Pumps function either by an electric motor or a diesel engine.

The Fire Fighting Pumping Systems ( Fire Fighting Pumps ) starts when the pressure in the fire sprinkler system drops below a threshold. The sprinkler system pressure drops significantly when one or more fire sprinklers are exposed to heat above their design temperature, and opens, releasing water. Alternately, other fire hoses reels or other firefighting connections are opened, causing a pressure drop in the fire fighting main.

Main Electrical Pumps (Electric Motor Driven Fire Pumps)

The Main Electric Pumps ( Electric Motor Driven Fire Pumps ) works on 3 phase Star/Delta Action AC supply. The Electric Motor Driven Fire Pumps are of high capacity than the Fire Fighting Jockey Pumps. These pumps start as soon as the pressure drops below the certain point, usually lower than the Jockey Pumps set point.

While Pumps working in emergency situation, if the dark out occurs then the Electric Motor Driven Fire Pumps will get off. This is the worst condition may occur when using Electric Motor Driven Fire Pumps, to overcome this disadvantage the NSC has an instruction to install a Diesel Engine Pumps which will turn ON automatically when the dark out (Total power failure in the plant) occurs.

The Main Electrical Pumps ( Electric Motor Driven Fire Pumps ) are designed to start automatically when the fire water pipeline pressure drops to a certain level. The pumps will be stopped manually only.

Diesel Engine Fire Fighting Pumps (Fire Fighting Standby Pumps)

The Diesel Engine Fire Fighting Pumps work the same as other Diesel Engines, starting with the help of UPS supply and utilizing diesel for running the Main Pump. The DG SET has a large storage fuel tank as a backup.

The Main Diesel Fire Fighting Pumps are designed to start automatically when the fire water pipeline pressure drops to a certain level. The pumps will be stopped manually only. A reliable system depends on design considerations such as fuel supply, combustion air, exhaust, ventilation, and engine cooling.

Fire Fighting Jockey Pumps:

The Fire Fighting Jockey Pumps is in jogging mode i.e. it’s just maintain the Water Pressure in the fire pipeline which is running around the Industry.

The water pressure to be maintained in the pipeline is in between 5 to 7 kg/cm2. Pressure transmitters are mounted on the fire water pipelines to monitor the pressure, usually 3 no’s. Will be installed or depends on plant capacity. When the pressure in the fire water pipeline drops below 5 kg/cm2, the Fire Fighting Jockey Pumps starts automatically to maintain the fire water pressure in the pipeline as per the set point.

When Fire Fighting Jockey Pumps are in auto mode then the pumps can be started and stopped as per the LOW and HIGH set points of the pressure transmitter.

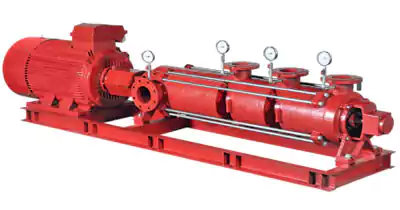

Multi Stage / Multi OutLet Fire Fighting Pumps offer many benefits: buildings need fewer pumps; pipe work and valves are reduced; the need for water storage tanks on intermediate floors is eliminated; and the loading on the building is reduced. The cost and space saving implications are significant: power requirements are lower, pumps rooms can be smaller and, in line with new EU legislation, there is no need to use pressure reducing valves to prevent over-pressurization of sprinkler heads. Driven by electric motors or diesel engines, Multi Stage / Multi OutLet Fire Fighting Pumps are available to satisfy any LPCB specification for automatic sprinkler protection in high rise and multiple story buildings.

Multi Stage / Multi OutLet Fire Fighting Pumps are used in fire protection systems in most tall buildings including offices, hospitals, and hotels.

The Fire Booster Pumps is a life-style product best suited for water supply for Sprinklers and Hydrants systems. It is perfect for use in homes, clubs, hotels, hospitals etc. Very aptly named 'Shower Joy pressure booster system' this product gives the user the pleasure of sharp, tingling jets of water while using the shower panel.

The Mono block Pumps come with easy installation features, greater efficiency and low maintenance cost. The compact shape along with the superior quality of the Monoblock Pumps ensures hassle-free service for agricultural, industrial and commercial sectors.

- Easy installation

- Very low power consumption

- Convenient three speed switch for setting as per need

- Material of Construction / Specifications

- Pump casing - Cast iron

- Impeller - Glass fibre polypropylene

Protect What Matters Most with Our Fire Fighting Solutions.